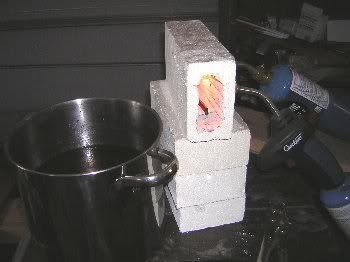

A propane torch in a kiln brick mini forge is what I've been using to heat treat blades for years.

Heat the whole blade up to critical temp - the point where a magnet is no longer attracted to it - then quench in warm oil (~120 degrees)

Check the steel with a file to make sure a file doesn't cut into it. If it does, the steel wasn't hardened properly either b/c the blade wasn't transferred to the oil quick enough or the blade wasn't at critical temperature prior to quenching. If that's the case, normalize the steel and try hardening again.

If it's good and hard, clean off the oil and pop it in a toaster oven (or the main oven if'n you're not making dinner) at 400 degrees. General rule of thumb for tempering is hold it at the temperature for 1 hr per inch of thickness. A knife is pretty thin. I normally do 45-60 minutes then call it good. That gives it time to come up to temperature and soak for a good amount.

If the steel isn't annealed, heat it up to critical and immediately bury it in hardwood ashes and let it cool slowly overnight. That won't be a full anneal, but it'll be close. It helps to put some hot coals in with the ashes as well. You can use sand in a pinch, but that won't be a full anneal either. Will you be able to notice it? Probably not.