this is what i do, here are the pics i promised you- seems like the radius curve will be easier and quicker- i have a big resaw blade on my saw- and dont like changing them out- so here is what i have done for my two glass bows.

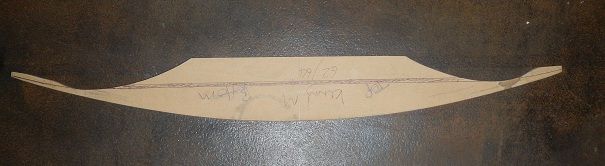

lay down your glass and lams that are going on the back of the riser, tape them down tight. draw a template pattern, with a very sharp pencil- no pen- as it will give you an off set mark.

i tape a lot more places- just did a few for the pic- make sure they are up snug!!

now when you make your template- you will have to accommodate for the tape- so maybe retape it in different places- and draw in the missing line sections!

i then combined that with the belly side profile from kennys plans, and you can see i just made the back a complete radius- guess i could have followed the profile out towards the fades- -just like kenny mentioned in his post above.

then i made a good sanding block- so i have 3 different radii to suit different needs

\\could have made it with 4 different radii- well...next time!!

i used some 36 grit paper off cuts from my lam grinder- or any good fabric backed sandpaper off your belt sander etc, and i taped it inside and outside with some tape,so its now like a mini belt. so now i can take the sand paper "belt"off and the block, rotate its position, so that the paper is in the correct place, and the tape is against my hand

VERY IMPORTANT.make sure the sides of your block are 90 degrees.

now after i have cut my shape on the band saw, and rough ground on the spindle sander- i can finish sand by hand.

putting the riser flat down on a surface, and the sanding block too- and then while sanding - everything stays 90 degrees.

then keep taking it back, and checking on the form- except now you have taken the tape off the lams, and are checking for good fit against the lams.

then...as kenny says cut out your ramps and sand and feather them, what i do here is take the block of wood that i cut off the back radius- and tape it to the riser in the middle-so now my feathering has some support- so i dont bust it.

all make sense?? i am confused reading my own ramblings!! :confused: