If you are going to make the same riser all the time you could get one of the duplicators.

I like to do everything by hand

Mark this is how I do it

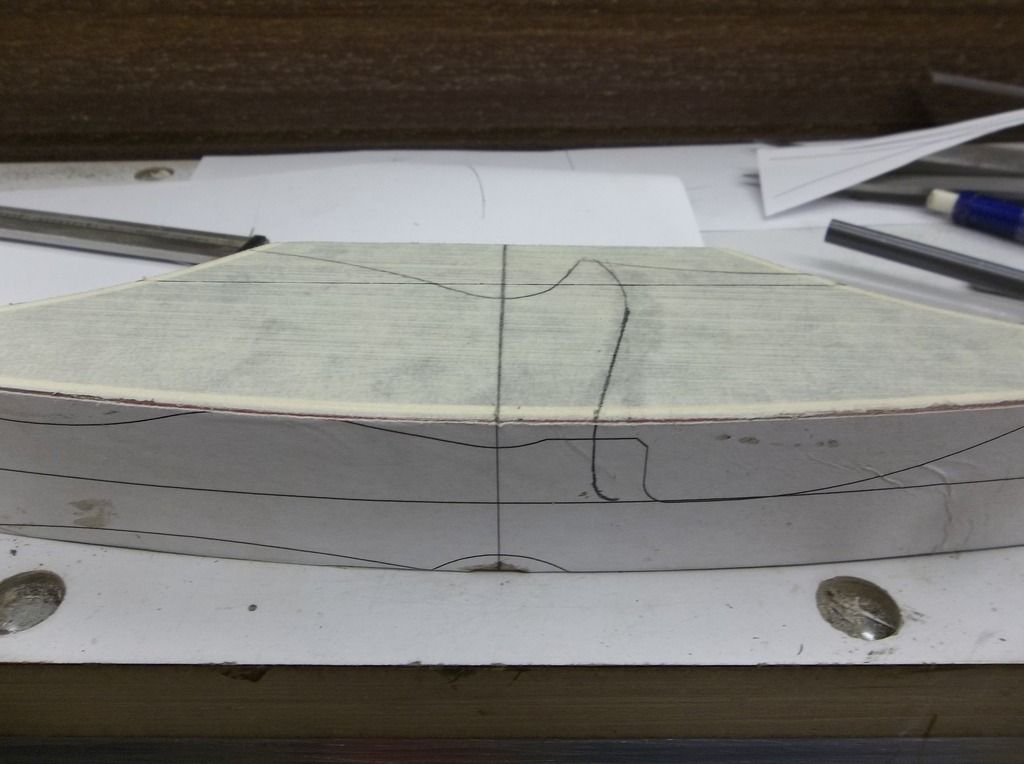

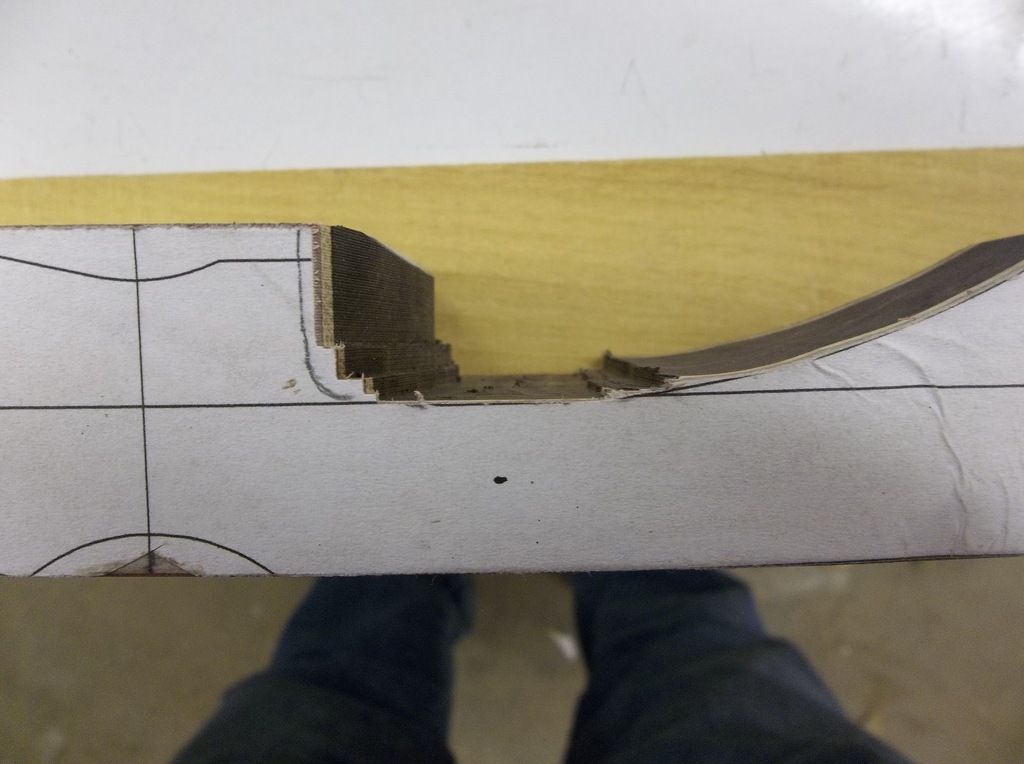

First I layout my lines

I use my pattern sander with a piece of pylwood to get up above the rub coller

Then I sand to the line all I can get with the 3" diameter sander.

http://www.bursforcarving.com/index.html

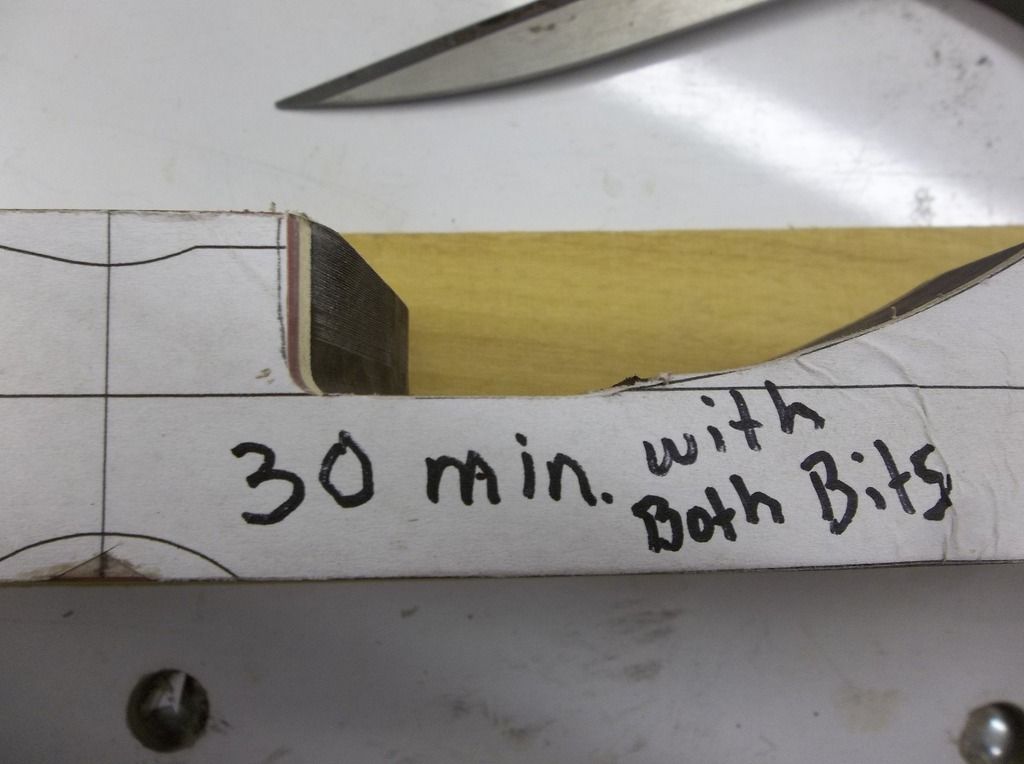

http://www.bursforcarving.com/index.html the one on the right I use first

1st rasp click on Rasp Type burs (FGR5BTN) This bur really cuts good!

2nd bur click on 1/4" Shank burs (BULLNOSE (RADIUS CYLINDER) SC-1SC

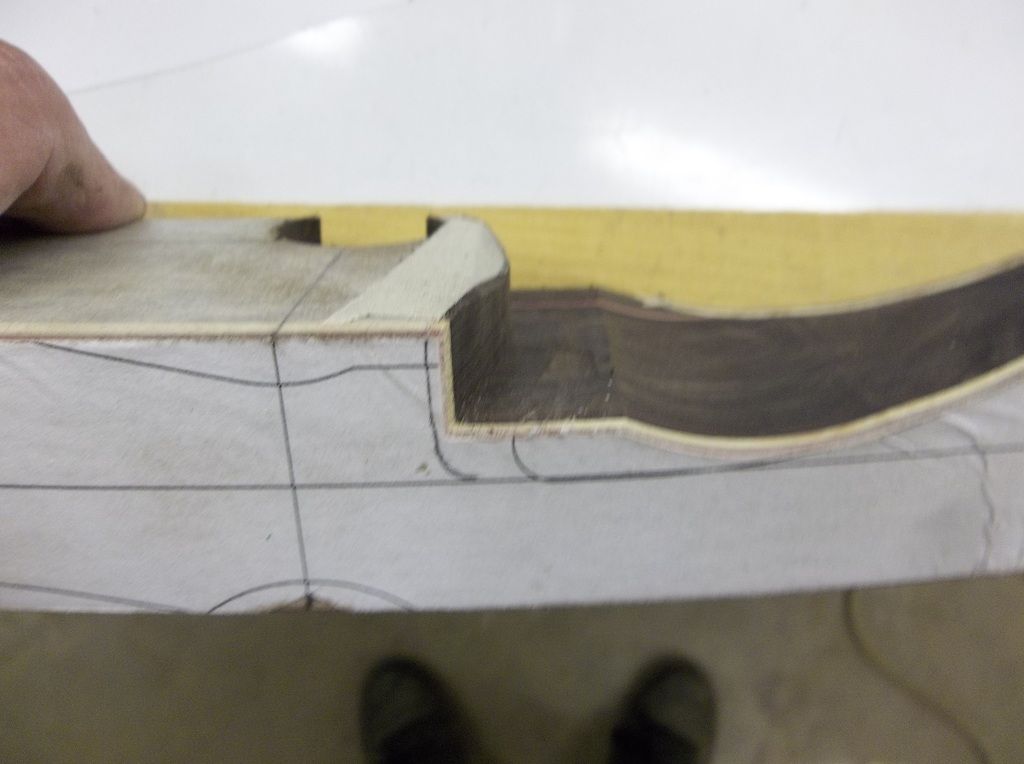

I take my patter sander off and chuck up the the rasp bur on the right. I use a larger piece of plywood on top of the drill press table. with the spindel handle all the way up I raise the table up to take a 1/8" cut.

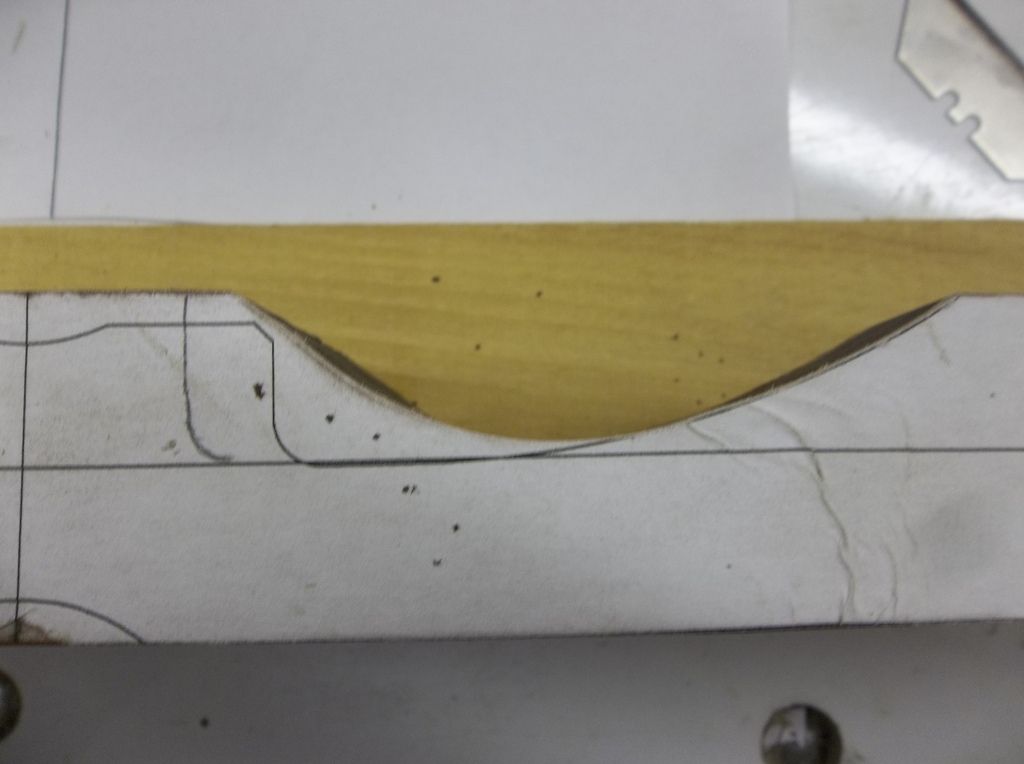

First pass, I pull and push the riser and follow close to the shelf line

I raise the table up more and make more cuts and stay away from the radius. now I am at .700 thick at the arrow rest.

Now I use the ball nose bur 1/4"

Don't take a full depth cut on the First pass.

With a firm grip follow the shelf line, go easy

I still have some hand rasping to do to finish off and relieve so the arrow only touches on one place on the site window