I cut out all the paper templates and covered then with a plastic film to make them a bit more lasting.

Glued the two blocks I had left over each other to get enough hight, drew the form and sawed in half. I screwed the pieces together as I was going to saw them that way but despite the specs saying 80mm because of some engineers brainfart the bandsaw can only cut 60-70mm thick pieces.

So I sawed them separate and then rescrewed them together. So_much_better_control on the small wobbly table with the shorter pieces compared to the first form.

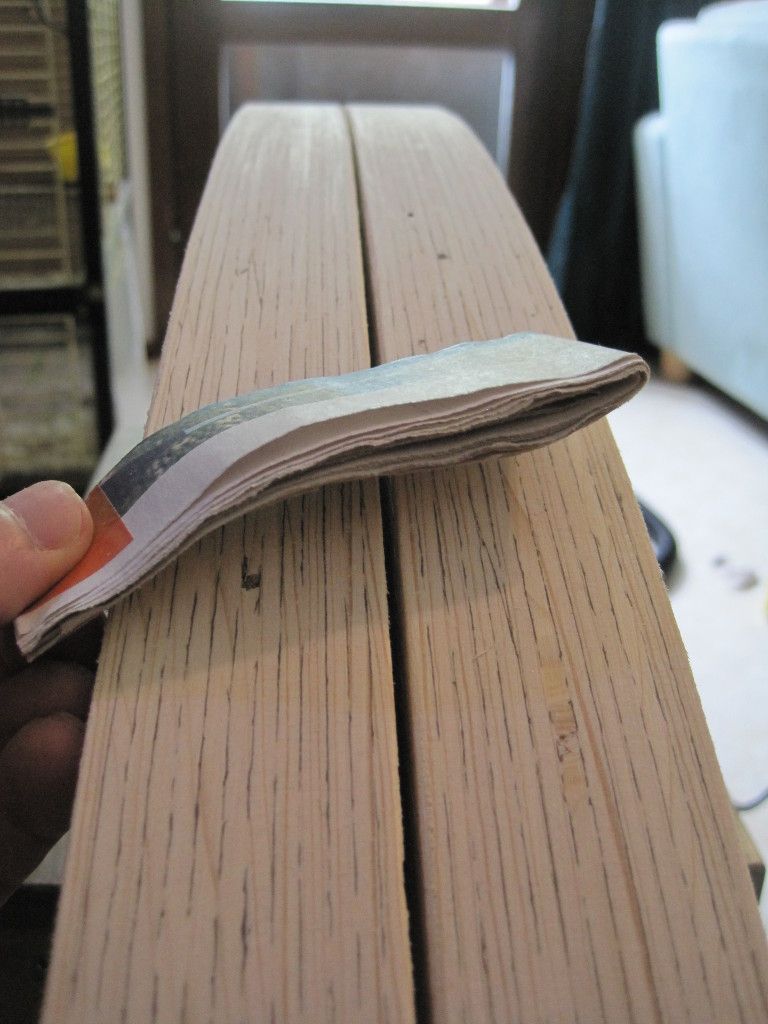

Some 40 grit (professional quality this time)sand paper and a sanding block I made back in gunsmithing school.

Some rasp for the rough work

I made a curve sanding aid by epoxying the sand paper to a piece plastic flexible enough to curve but thick enough not to sink into any dents. Simple and effective.

Checking and rasping to get it squared.

After I was satisfied I put some stacks of paper between the pieces and spread some epoxy on the tops. Being very thin, most of the epoxy got sucked in the wood. Makes for a nice hard surface.

Now the harder part of getting the together....