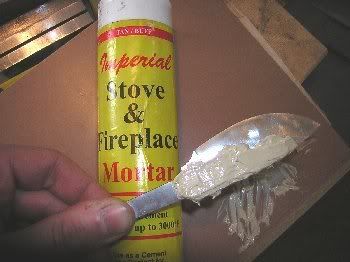

You could just do an edge quench or cover the spine area with clay, satanite, or a high temp fireplace mortar.

Get the blade ready for heat treat and coat the spine, then heat to non-magnetic and quench. Clean it up and temper as you normal do.

To highlight the hamon you can selectively polish the blade, or etch it (much easier)

I usually etch for 20 seconds in a 1:4 mix of ferric acid:water or a 1:1 ferric:white vinegar (what I etch damascus in).

After etching my blades look like this:

The opposite of what we're going for.

I use Flitz polishing paste to rub the blade out. Put a little on the blade and rub with your fingers in a circular motion, being careful not to overwork one area. When the flitz loads up and becomes black, wipe it off and put some new paste on. When that's finished wipe it off and buff with an old t-shirt to get rid of the residue.

At this point, the blade will look like this

The hard steel releases it's oxides much faster than the soft steel.

To get even more contrast between the hamon line and the grey back, take some more polishing paste and carefully polish the spine down to the line. Now you'll have a polished light grey spine, a satin or mirror edge, and a dark hamon

It'll help to switch pastes for that last step... mixing red rouge with honing oil was recommended to me by someone who worked some with Don Fogg.