Connect the dots on the back of the sheath with the grooving tool and groove front and back a bit extra deep where you plan for the stitching to end........I forgot to take a pic of this.

Time to do the stitching. I use between 7 and 8 times the length of the total stitch length of thread......so if the row of stitching is 5 inches long, I will use 35 to 40 inches of thread.........maybe a bit less if the sheath is thin. It's not cool to get almost to the end of the stitching and find out your thread is too short.

Find the center of the thread, pull the first half through to the mid point and roll the other half up and tuck it inside the sheath to keep it out of the way.

Pics are better than words here I think. Pull the thread as snug as you can.

I thread the first half all the way to the far end and then take the second half and thread it up where the first one went down and down where the first came up.

At the end where the 2 threads meet. I tie an overhand knot and run the tag ends back down and head back towards the starting point. The stitching will be doubled up in the grooves......fortunately we made the grooves slightly deeper here to make room for the extra.

I find this to be a good way to get the needle through the holes when they are snug, and during the last few stitches it should be quite snug. Grip the needle with a pair of pliers, and use your thumb to push the pliers so the needle passes through the hole.

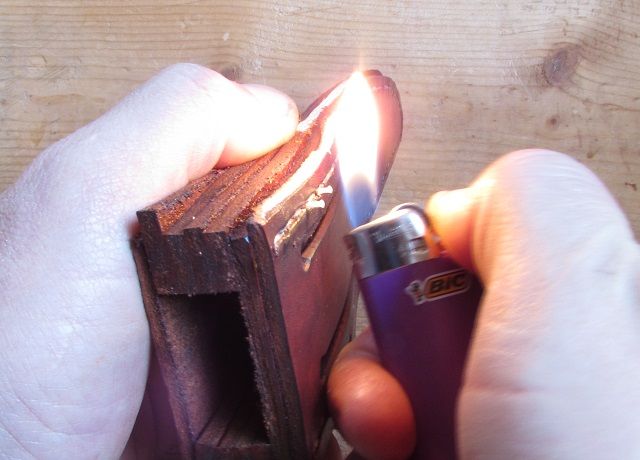

After going over the stitching for 3 or 4 holes, pull the tag ends as tight as possible, cut the remainder off about 3/16" long and melt the ends back using the side of the lighter flame.

The thread will melt into little beads that will not be easily pulled back through the holes.