Ok finished up this little bow for my 4 year old nephew. I am new to the bow building and learn on every bow and this one was no exception. It started as a failed bow back at MOJAM. I was trying out power tools and learned although you can make one fast you can mess on up even faster. So what was a bow for me now as to thin and short so I laid it to the side and figured my nephew need a bow.

So when tillering this one. I heard a pop and sure enough found a crack at the fade and handle. I decide to chase down another ring and found that got rid of the crack.

On with tillering I went. once to a short string I noticed that string was really closer to the one limb then the other. I scraped a bit on the one I thought was stiffer and it only made a small about of difference. I decide to heat up the weaker on and flip it's tip to match the natural on the other side. Once I did that the till was almost spot on. I evened it out and did a bit of side tillering to keep them from getting too thin.

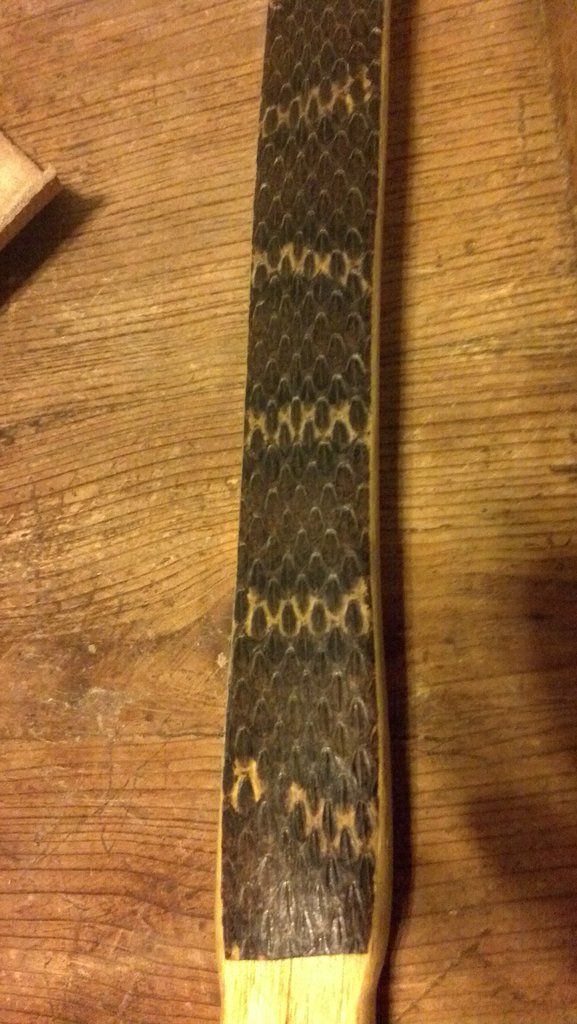

This is my first skinning job. It had a couple of holes in it so I trimmed of what I know would not be on the bow and put them behind the holes and that seems to really hide them.

Well now I can focus on doing my swap and trade bows.

Oh it is 42" ttt and is pulling about 12lbs at 20"