I've been using System Three's WR-LPU for over a year now and I really love it.

It's a marine grade water based finish that uses a catalyst to increase it's durability. (In my opinion it's as durable as the 2 part epoxy finish)

I've used just about every type of finish for bows, including the ones listed previously in this thread. Of all the finishes I've used, I like WR-LPU the best for a satin finish (I prefer 2 part automotive urethane for a high gloss finish).

There's a little bit of a learning curve getting used to how it sprays since it's water based, but once you get the hang of it, it works excellent for bows.

It's durable, flexible, dries fast, has a nice satin sheen with no milkiness, and has absolutely no volatile odors. (you could spray it in your home and your wife wouldn't even know it

)

It's not cheap to buy, but I've found that you usually get what you pay for.

This is where I buy mine...

http://www.jamestowndistributors.com/userportal/show_product.do?pid=70&familyName=System+Three+WR-LPU+Linear+Polyurethane+Topcoat+

It's actually cheaper to buy it from Jamestown than it is directly from System 3. If you get on Jamestown's mailing list, they send out free shipping offers about once a month. When I'm about out of finish, I keep an eye on my in-box for their free shipping code and then buy the finish when I can get it with free shipping. That probably saves an extra $15 or $20.

When I finish a bow, I seal and fill all wood surfaces with automotive urethane because I like the way it fills and sands.

After everything is filled and sealed the way I like it, I sand it down with 320 and spray the whole bow with 3 coats of the satin WR-LPU (about 1 to 2 hours between coats).

I let it dry for 2 to 3 hours and then lightly spot sand any imperfections or little goobers out with 1000 grit, and then put 2 very light mist coats on the bow (10 to 15 minutes between coats).

The next day it's ready to put in the box and ship out to the customer.

A few things to keep in mind when using it...

-Have very good lighting so you can see exactly how it's going on the bow (it's very easy to spray it too heavy, resulting in runs and sags)

-It's best to use a spray gun with a pressurized cup because it is a thicker than most solvent based finishes (I use a Fuji HVLP turbine sprayer with a pressurized cup)

-Thin it with distilled water (4 parts finish to 1 part water). Make sure the catalyst is mixed in the water before it's added to the finish. Use 8 drops of catalyst for every ounce of finish (not including the amount of water you're adding).

-Don't spray it on heavy or it will run and sag. The water in it doesn't evaporate as fast as a solvent would, so spray on light coats. It initially has a "orange peel" texture when it's wet, but it will level out as it dries. This takes some getting used to if you accustomed to spraying solvent based finishes.

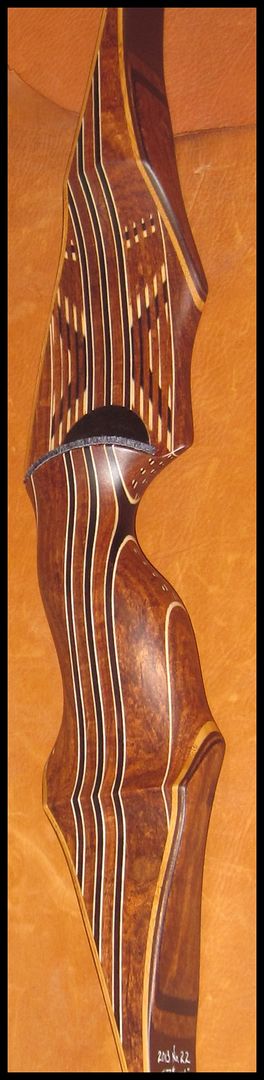

Here's one of the end results of spraying the WR-LPU...

I hope this info is helpful to any of you guys who are interested in trying a good quality water based bow finish. I wish that I would have found this stuff years ago.