I'll post some images later of crested arrows.

The holes on the smaller end are 3/16 (for nock taper ends). The holes on the opposite end are 11/32 for 5/16 shafts and 3/8 for 11/32 shafts. The jig in the drill is a wooden dowel with a short piece of gas line hose to snugly fit the shafts into. I use a variable speed cordless drill. I lie the drill on its side so drilling the guide holes at the height of the chuck is important.

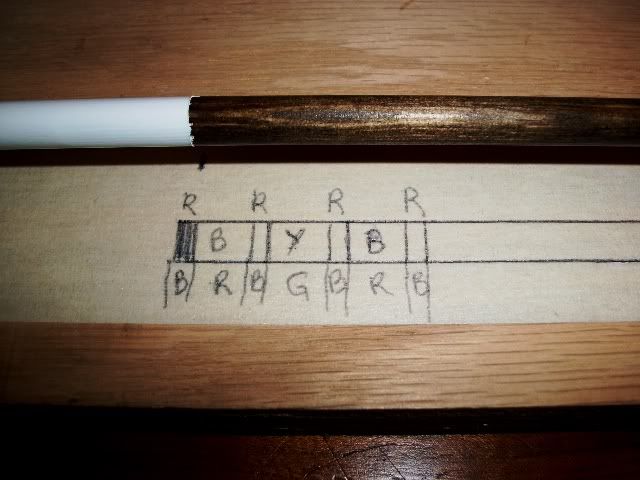

All the wood is scrap plywood. I cut the short end (height wise) so that I can slip the crested shaft out so that I don't have to bring it back through the guide hole.

I have it set up to crest with my left hand while the right hand controls the drill speed. (low rpm)

With the control points close to each other it makes arrow wobble virtually nill.

Hope this makes sense.

Bud