Here is my first attempt at a build along so please forgive anything I might have missed or don't explain in enough detail. I have been on a quest for the perfect hunting quiver for most of the summer. I have tried a lot of different quivers including bow quivers which didn't suit me either. I have been making back quivers and other leather items and thought I could make a side quiver. My apologies to Mr. Catts for the idea. I modeled mine after his with a minor change here and there so I can't take credit for the design.

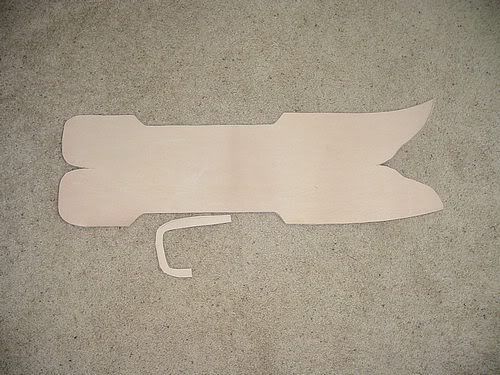

I started by using graph paper to draw to scale the quiver that I envisoned would finally make me happy. Sorry I didn't take a picture of this but you get the idea. Next I pulled out a roll of meat packing paper and sketched out the design full size and cut it out. No pic of this yet. I hadn't planned on doing a build along at this point. The next thing is to trace the paper cut out onto the leather and cut it out. This is about the time I thought I could take pics and do a build along.

I also cut out a piece to be sewed into the business end I think this is called a welt. (This is the little U shaped piece at the bottom of the pic) I ended up using two pieces of this material in the final design. I thought after folding the leather together and clamping it I would have more room to insert a piece of foam to hold broad heads.

Here are the welts glued into place.

At this point I thought it would be a good idea to stain the leather. For this I used a kit I bought at Wally world that is used to paint model cars and planes. I don't have a pic of the kit but it has a glass jar to hold the stain and a hand operated nozzle that blows air from a can of propellent. This actually worked really well (after I figured out how to use it).

A pic so far.

While I was learning to use the sprayer kit I kinda got a little heavy on the stain in places and got the bright idea to add some stragetically placed camo with the stain.

If you look closely you can see the striping. I thought this would maybe help break up the outline a little.

Since my wife was out of town over the weekend I was making this and it was scorching hot in the garage even at 9:00 in the evening I had another bright idea. Guys here is the disclaimer....don't do this if there is even a remote chance your wife will find out...

I brought my portable work bench into the living room and set my portable drill press on it. I then was nice and cool and ready to drill the holes for the stitching while watching the Braves game.

There will little pieces of leather all over the floor so guys if you do decide this is a good idea make sure you know how to actually use a vaccum cleaner....

After the holes are marked I used a little tiny drill bit just larger than my needles and drilled out the holes. I used wax coated heavy duty thread (more like small cord) for the stitching. Sorry didn't think to take a pic of this.

The next step is to attach a D ring for the shoulder strap. I used glue to afix this piece to the quiver before I started punching holes and stitching. I have seen my other projects and it is really easy to make a complete mess if your holes in what you are attaching and the holes in what you are attaching too are off line.

The strap that holds the D ring is sewed onto both sides. This is kinda my first design flaw. There isn't a lot of room in there to find and fit the needle into the hole for the return stroke.

Now on to the rear flap glue up and stitching. I used a fair amount of glue and clamps to get this part lined up right. I didn't want the quiver to take on a bend in the wrong spot. Matter of fact I didn't want it to bend at all. Take your time and get this right you'll thank yourself in the end.

The holes for stitching the rear flap are marked and drilled just like the front so no pic of this either.

The second strap for another D ring is cut, stained, glued and stitched into place just behind the opening to get your arrows out. Don't do this!! This is my second design flaw and first major one. The quiver will not hang right with the rear attachment point so close to the center line of the quiver. The quiver will want to hang horizontal and at times point end up and dump your arrows on the floor. This was a hard lesson learned and a lot of time wasted making and attaching this piece. Sorry I was just a little unhappy with myself here so taking a pic was the last thing on my mind. I almost lost my religion....

Instead of attaching the second D ring to the quiver just past the opening attach it to the rear. It will hang nicely and stay more or less where you put it.

Continued on next post...