Thought I'd show what I'd come up with to control temperature and the atmosphere in my forge. This is just a simple NC Forge Whisper three burner atmospheric forge. I wanted to know and be able to control the temp in my forge more accurately so a few years ago I purchased this digital pyrometer/thermocouple. It worked so well I bought another thermocouple and wired the two thru a three way toggle switch so I could switch from one thermocouple to the other. One is permanently installed in the forge the other is mobile so I can stick it into the pipe I use for heating my blades during heat treat.

OK here a few pics.

Inside of the forge with a piece of 2"ID stainless tubing, you can see the thermocouple in the top of the forge. When you buy your components you can get a ceramic tube to protect the probe from the nasty environment in the forge, I'd recommend it.

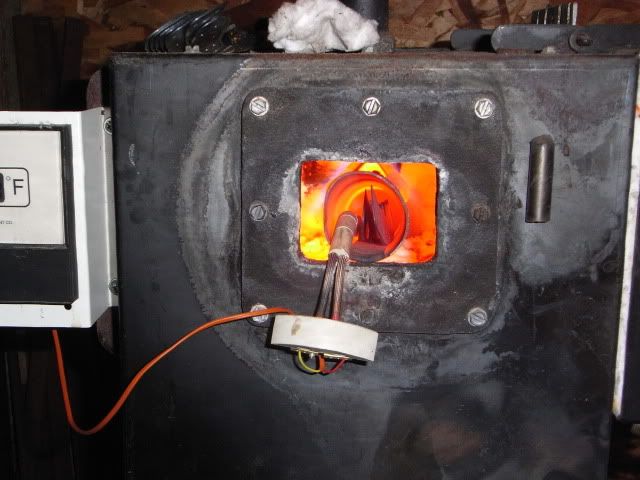

This is how I drilled the forge wall and installed the probe and the back of the Pyrometer.

Looking from the front, dip tank on the left, she'll hold just over five gallons of quenchant.

Another front view with the thermocouple stuck in the heat treat tube. When I put a blade in the tube I put a small piece of ceramic wool in the opening to close the tube off. This makes it easier to control the heat and also helps with the inert environment inside the tube. I just turn the gas off and on to control the temp; it's pretty easy to keep in within a 25ish degree temp range, essential with some steels. That's a strong magnet stuck on the right, nice to have real handy like that...

Here you can see the inside of the HT tube I welded a couple uprights to hold the blades straight and off the wall of the tube. You can see a piece of angle I welded on top of the pipe also; this protects it from the burners which inter from the top on this forge.

Post heat treated and quenched blade, since I've added the HT tube and went to the Parks quench ant my blades come out clean, straight and hard.

Hope this answers a question or two... Thanks for looking.