Good work Matt.

Yes, I would do liners, also, when you peen the pin, it helps with strength to have some sort of washer under the peened heads of the pin, that helps reinforce the pivot.

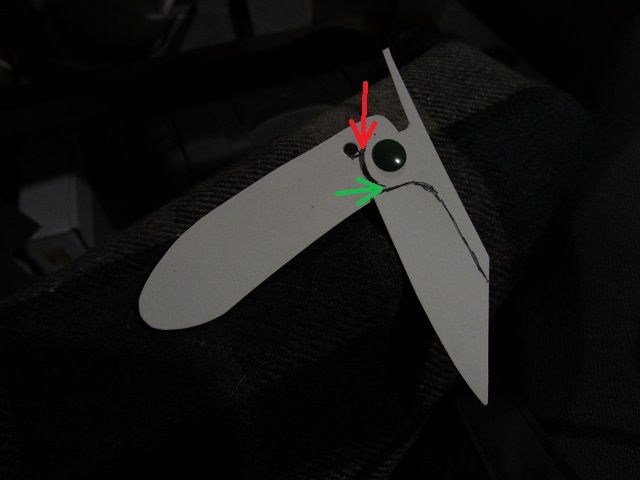

like this one.

Anyway, I did this up real fast but it looks like you have it figured out anyway.

The pivot pin should be lower than center of the handle as shown by the blue lines.

The important lines are shown in red.....kick at the tang is thick enough for strength, enough meat near the pivot.

Green dot is your stop pin.

Adjust the tang around the pivot to clear your stop pin (Red arrow) and in the full closed position to stop the blade in the position you want it to sit(green arrow)

Full closed position, showing where to lay out back spacer.

When you peen the pin, put a shim of brass in between the blade tang and liners on both sides......aluminum can will work too. Peen the pin equally on both sides a little at a time until the blade gets snug, then remove the shims, and peen a tiny bit more until you have the amount of friction you want in the blade pivot.

Put a drop of oil in the pivot hole before you peen it.

I like your design.

Darcy