I rough sand the glass with 80 grit right beneath the overlays, and all contact surfaces on the overlay parts. Everthing is cleaned with acetone. Now is the time to work all the kinks out of your clamping system. Overlays will slide all over the place when clamping, so be prepared.

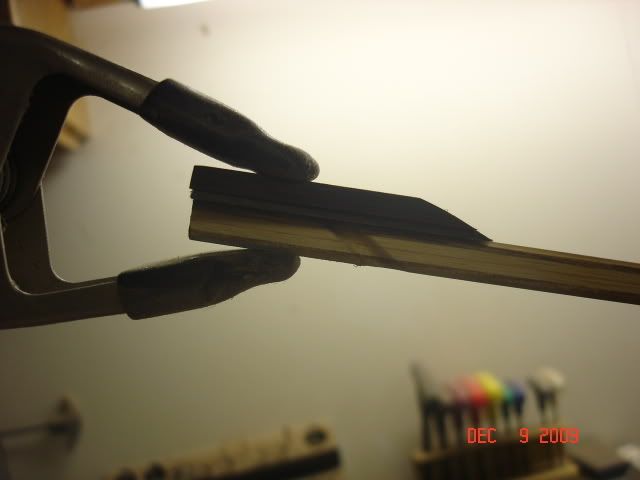

I dry run everything. Here is a tip clamped to check for fit. It's always good on these straight bows, unless the surfaces are not flat, but on recurves or R/Ds, the limb tip has some curve to it. This curve will cause problems if your pieces are too thick.

I now mix up too much Smooth-on epoxy.

After applying epoxy to all glue surfaces and clamping, I will wipe the bead off. I want it to require as little sanding as possible at that joint later. These spring clamps are perfect for tips. You can move them around to get even clamping pressure that holds the slippery tips in place.

Here is the riser overlay clamped up. Notice the side clamps. That keeps the overlay over the bow's surface. Without those it would slide right off the side of the bow.

Next, my three headed monster is lowered from the ceiling where she sleeps. I move the lights to within 12" or a little more, depending on the ambient temp. I only want around 120-130 degrees here for 4 hours. I forgot to take a photo here, so this one is from another build.