Sorry I have to come up for air every so often! Still posting. Yea it has flung an arra or two.

After all of the nocks are filed it is time to put a string on the bow and tiller it. The way that I build a bow there are two ways that it is tillered. The first phase is to make sure that the limbs are pulling straight back from the bow and not twisting. To check this you look at the bow down the length and look to see if the tip of the bow is pulling to one side or the other. A quick look at this one showed that the limbs were straight at low brace. I then use a 20 inch tillering stick on the bow to check it at 1/2 draw. In this next picture you can see that the limb tip is pointing to the pencil. To balance the limb I had to remove a small amount of material from the strong side of the limb. The strong side is the side it is pointing to. If you look carefully you can see the pencil mark on the tape that shows which side I needed to remove the wood from. The reason I mark it is because it is easy to get twisted around when you unstring the bow and lay it down.

After a few tries I had both limbs of the bow pulling straight. Then it was time to check the balance tiller of the limb top limb to bottom limb. To do this I measure the fades using a bow square. I want the lower limb to be 1/8 to 1/4 of an inch stronger than the top limb.

The initial readings were 7 3/16 inches and 7 1/2 inches. To balance the limb I sanded the lower limb using 120 grit paper. I use a long straight edge and remove a few swipes from each side of the limb and then I sand the glass surface using a rubber sanding block. Once I have the limbs in balance I put the bow on my tillering tree and view the limbs from a few feet back and I also watch them bend. This is also when I check the initial weight. The Marty 300 came in at a whopping 82#. Just right for a neanderthal! What am I going to do! Oh April Fools day was a couple days ago. It actually came in at 65# at 28". This is not too bad. I am aiming for 57# at 28". A tiny bit hefty but the bow will end up in the neighborhood. Notice the balance in the bending of the limbs and how the top and bottom tips are similarly balanced above the black line. This is a good thing.

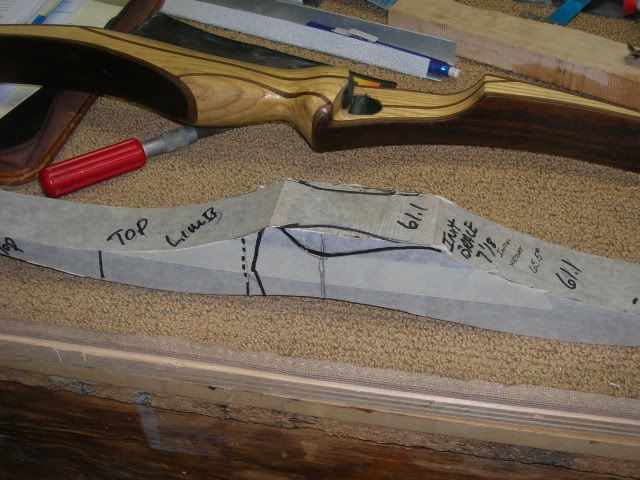

Weight loss is accomplished by thinning the width of the limb and the thickness. It is a slow easy process with continual check of the tillers. It is easy to go slowly and keep it balanced. With the bow down to 60 # it was time to move forward and really make this thing look like a bow. This next photo shows the initial layout of the bow. I used a black marker to make it easy to see. normally I use a pencil. I also marked all my little notes with marker so you could see them. Weight and tiller measurements don't get lost this way.

Additional layout markings.

Remember that blade I mentioned? It is again time to cut fiberglass...To cut out the riser I use a 3/8 6tpi. I have a number of blades marked FG.

CUT AWAY!

and how I cut the shelf out.

I then use a hack saw blade to continue the sight window cut down to the shelf. The next step is to start rounding the square blocky riser in to a thing of comfort and beauty. This is one of the most exciting phases of bowyering because you go from Blocky to comfortable in less time than a glue up!

pete