Started to cut the glass and masked it with blue painters tape on the shiny side of the glass!

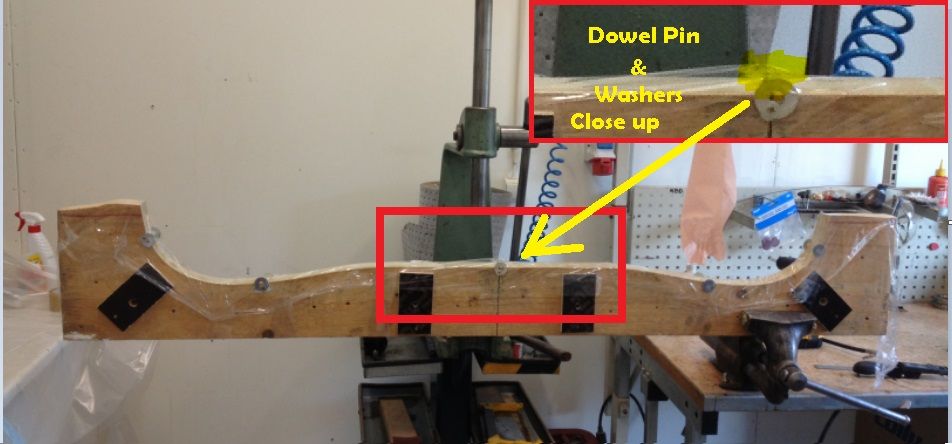

I also drilled a 6mm hole in the bottom / center of my riser, I also drilled and glued a 6mm dowel pin in center of the bottom form:

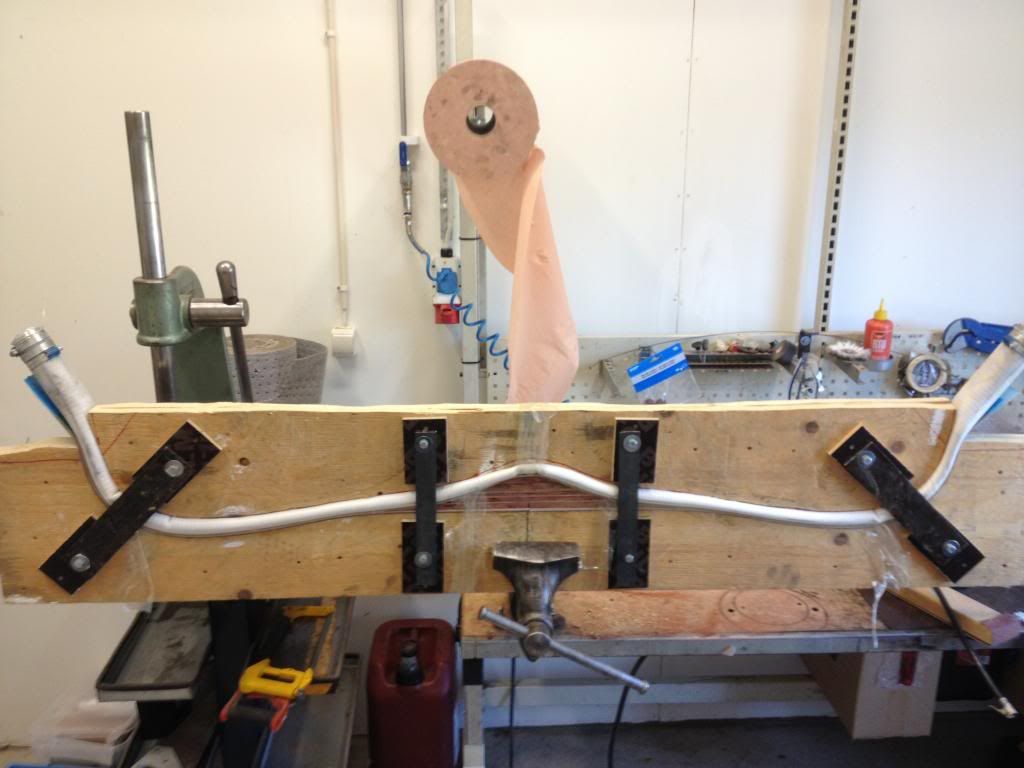

Put some painters plastic on my bench and form and suddenly my shop now looks inspired by Dexter

Lay up from Right to left on the pic (Bottom of the form and up) starting with:

0,050” Clear Glass (cut in half because of the dowel pin)

0,110” Taper 0,002” Red Elm (2pcs because of the dowel pin)

22” Riser

0,063” Paralell Red Elm (2pcs glued together with CA)

0,050” Clear Glass

Before dry run and glue up I always testing my air hose for leakage with 5bar and a bucket of water for a couple of minutes!

I always do a dry run mostly to see if fadeouts are OK!

On top of the bow and between the airhose I use a 0,040” aluminum pressure strip

I mix equal parts of smooth-on in paper cups and spread it with a filler spreader, we don’t want any dry spots so a lot of expoxy on all sides! Wet to wet!

It isn’t that messy if your organized, I use plastic gloves at least 3pairs each glue up!

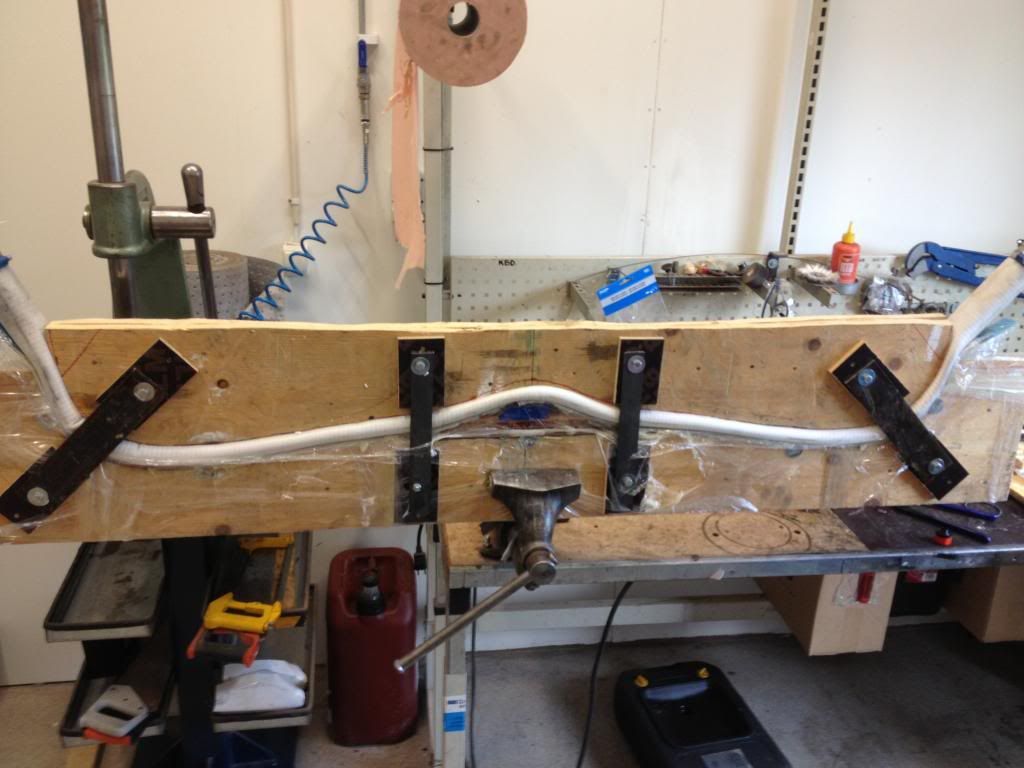

Couldn’t take any pictures during the glue up, but here is a picture when everything is in place before cooking 6-8h @ 170F

As you see I use a lot of tape to keep everything in place, it get really slippery when its glued!

When all laminates and pressure strip is in place and taped I screw the top of the form in place and fill the airhose with :

10-15PSI (0,5-1bar) then I wait approx. 2minutes

30PSI (2bar) then I wait approx. 2minutes

45PSI (3bar) then I wait approx. 2minutes

65PSI (4,5bar) if everything is looking good I take a piece of scrap wood and scrape of the epoxy that has leaked out on the sides before I put it in my hot box for 6-8h @ 170F

Now its just waiting…..

I open the lid on the box a couple of times to check pressure and temperature!