Plywood is always curved, so turn em to help take it out. I had to add a .110 pc of plywood in center that I sanded to thickness to get 1.5" plus just a little, the glass I checked was .010 oversized width.

I clamped it to the bench and was surprised to find it was good and flat end to end and corner to corner...

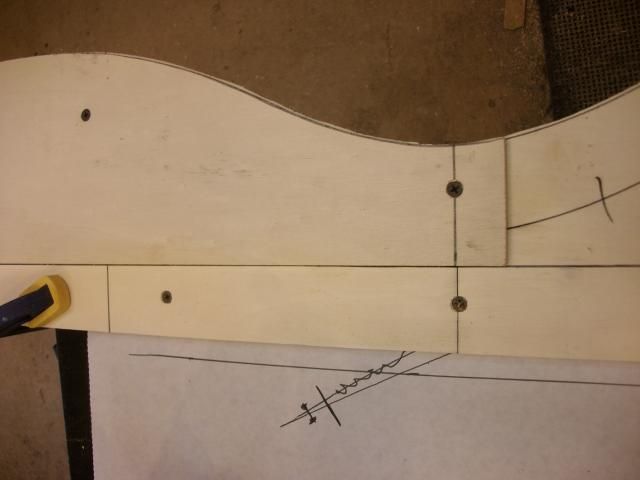

Ready to glue/screw together.... Remember, no screws where the router will run!!

Glued, screwed and tattooed. Bandsawed on waste side of line I marked an A on both pcs to keep everything matching each other...

I also mark the waste side of line to cut, don't even ask why!! :rolleyes:

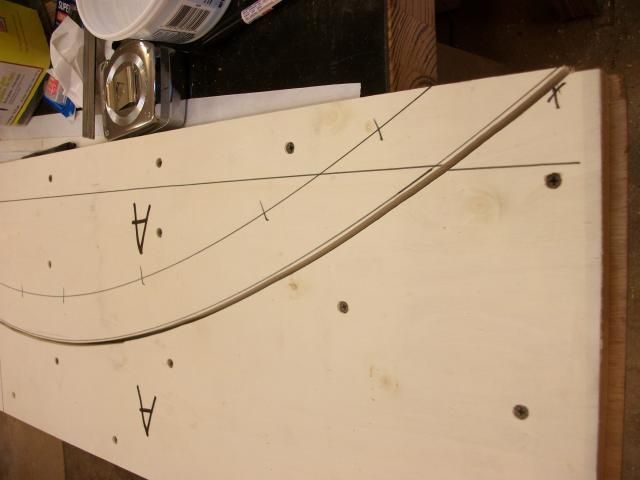

Template screwed onto form, and clamped to bench for safety, you have to push down on router to keep bit square with face of form...

Here you can see why the inch past center on template, gives the router bearing a place to run so you can get to center. Make sure the template is good and flush at the centerline when you flip to other end...