So I got some time to work on the bow this afternoon and I was able to get quite a bit done. I finished shaping the piece of ipe, first down to thickness, then to the width profile to match the bamboo.

At the fades it measures 1/2" then it tapers down to the tips to around 7/16". I realized that wasn't enough once I got it into the form to test clamp it. I'll take it down to 3/8" once it take it out tomorrow like Macbow had said.

I bent the handle after I finished preparing the stave. Following some instructions on an old Tradgang post I managed to heat bend a little curve into the handle that holds when taken from the form.

I would imagine all that heat probably damages the wood fibers, so like so many have said, I don't think the technique could be used on the limbs. Though some testing would need to be done to verify that. But where the handle area is it won't affect the rest of the bow if the wood was weakened. I didn't heat too close to the fades just to be sure. So if anyone says you probably can't bend 3/4" ipe, here's your proof.

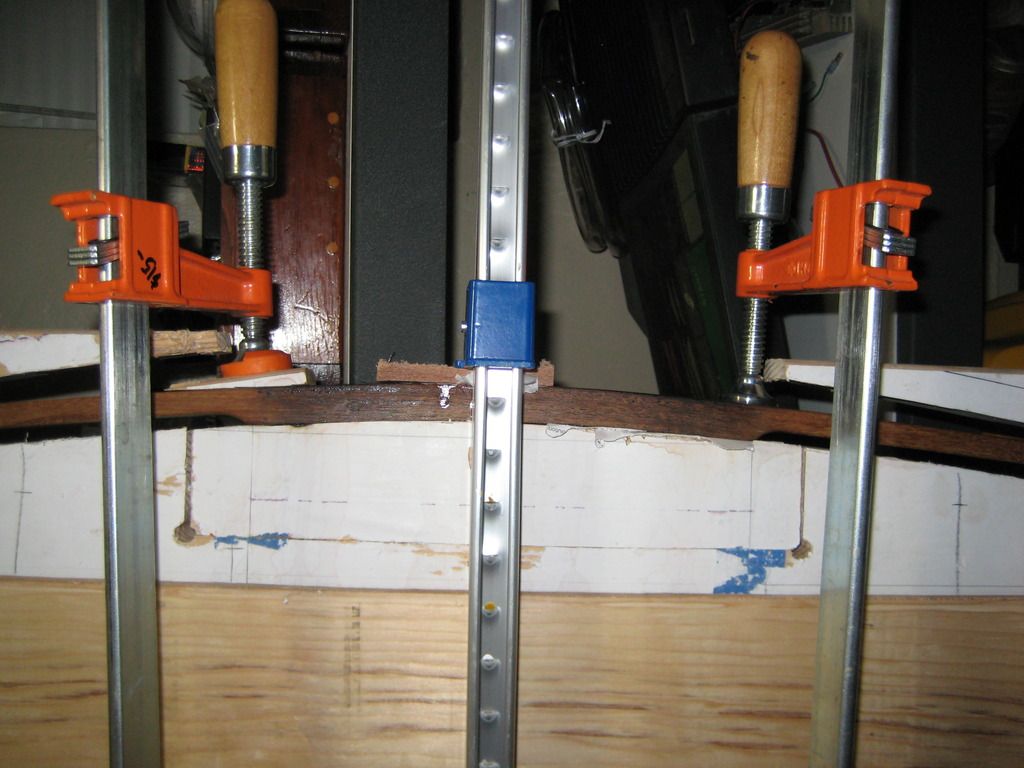

Just a little past this point is as far as I felt comfortable tightening the clamps. I used a heat gun and got the wood nice and hot. As others have said in other posts, little bits of black tar looking stuff comes out of the wood and it smokes a bit once good and hot. I alternated heating and clamping until I made it all the way to the form.

I may have gotten the wood to bend as far as I needed it to without heat, but I doubt it would have held its shape after unclamping. I wanted it to hold it's shape to reduce the chance of the handle popping off later down the road if the glue failed.

At one point I placed some paper shims in the center of the handle to bend the handle a little more than the form would allow. What bend I did get is probably about the limit with a 3/4" thick board, as I clamped it down with the shims in place a little bit of wood at the apex of the curve started to splinter

. I stopped there and called it good. You can see in pic above the center blue clamp, that is where I took some thin super glue and clamped the splinters back down.

I left it in the form for tonight, I figure it should help the handle take set better, I'm happy with the slight bend I got, I think it will look real nice when it's finished.

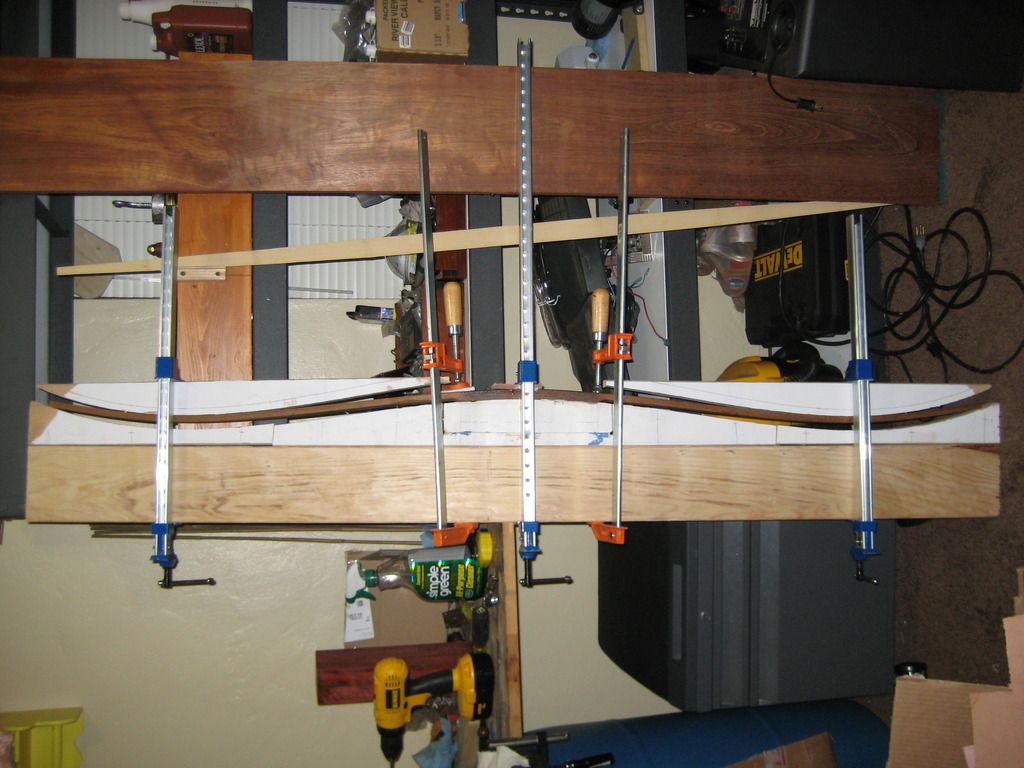

While it is in the form I figured I might as well start to develope the bends in the limbs.

It was at this point I realised I needed to taper the limbs more. Looking back at Macbows last post I realized I needed to take the taper down to 3/8" at the tips.

One question I had was about the tips of the bow and their relative bend to the rest of the bow. It was my understanding that with a R/D bow, you want the tips, maybe the last 8-10", to be relatively stiff, so most of the energy is stored in the first 2/3rds of the limbs. So the tips kinda act to snap the string. So if I taper the ipe both in thickness and width, will I still get those stiff tips I'm looking for? It would seem to me like the two tapers would cause the tips of the bow to bend uniformly with the rest of the limbs.

Anyway. this last pic is just a close up of the clamping pressure on the limbs. I'm afraid to try and clamp them all the way down for fear of them breaking.

Will tapering them down the last 1/16" allow them to bend as far as I need without breaking. I wanted to put some shims in the form at the tips to give maybe another inch of reflex, will I be able to do that?

Sorry for all the questions. Thanks for any help offered. I'm excited that it is starting to take shape, hopefully I can get it glued up and start tillering it this week

.

Anyway, thanks for all the advice so far. I'll post some more pics once the bow comes out of the form.