A while back I bought the plans from Jim Thorne's Build your own bow 62" take down.

I modified it to a one piece, and I have always liked the look of the glass cut out on the back of the riser.

It will look like a take down without the bolts.

I will also do a footed riser. I am going to use black phenolic 1/16" for the riser.

I'am shooting for 35@28

I had some Curly Walnut and Koa from a build before. So walnut lams and walnut and Koa riser.

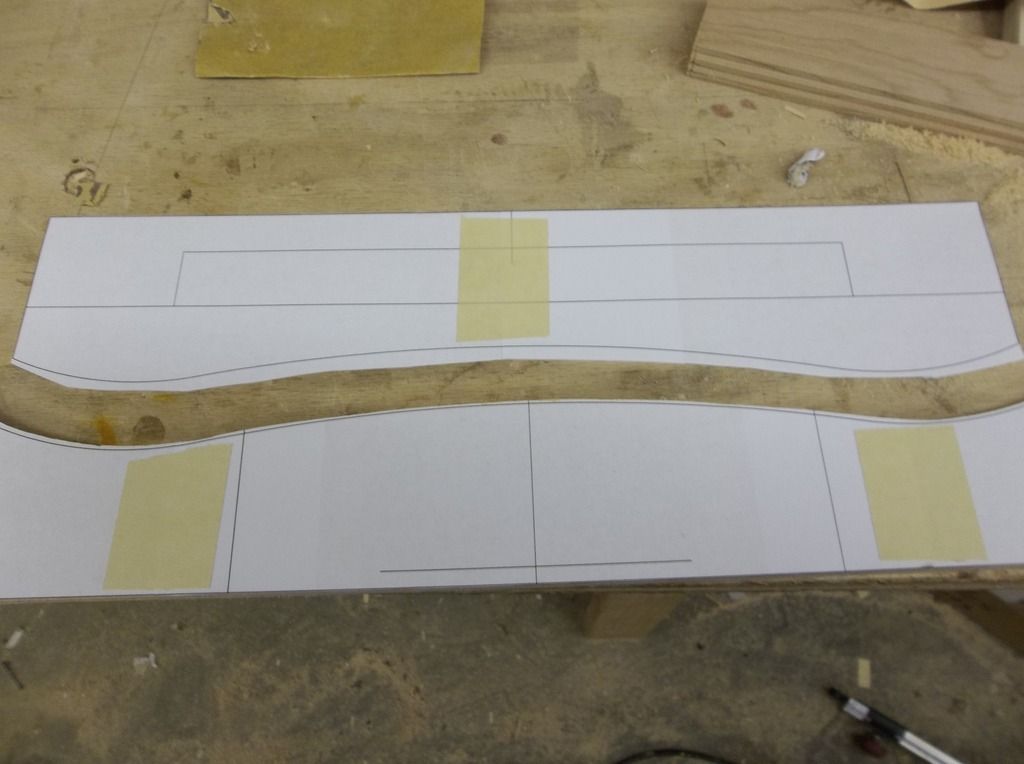

I drew it up on the cad program a printed the footed riser templates.

Here a picture of jim's bow.

Here is the top half of the riser template, but I started with the bottom template.

I glued the Paper template to some 3/4" plywood and started sanding to the lines. back and forth checking the fit.

no laser cut templates for me.

I sanded a piece of scrap wood to 1/16" for the templates.

So I got it as close as I could and wrapped my 1/16" piece and buttered the wood templates with smooth-on and clamped it all together for a day.

The glue will fill the voids I have.

I also have to mark the templates THIS SIDE UP and the riser wood also.

The dry run looks really good, so I sanded my riser woods with the pattern sander and my new templates and glued it up

The wood is curly Walnut and Koa

The top piece is the walnut and Koa cured and thickness sanded. And the bottom is the rest of the walnut.

I made the second riser template same as before.

I traced the lines and to the bandsaw to rough cut it.

[url=http://http://http://http://http://http://http://s1293.photobucket.com/user/osagemark/media/BYOB/100_0756.jpg.html]

I thought I had more pictures but here it is all glued and thickness sanded.

I did not have enough walnut so I glued some Pine on top.

All the pine will be cut off after the bow is glued up. more on that later.

While this was going on I made the form for the bow

[/url]

Going hunting